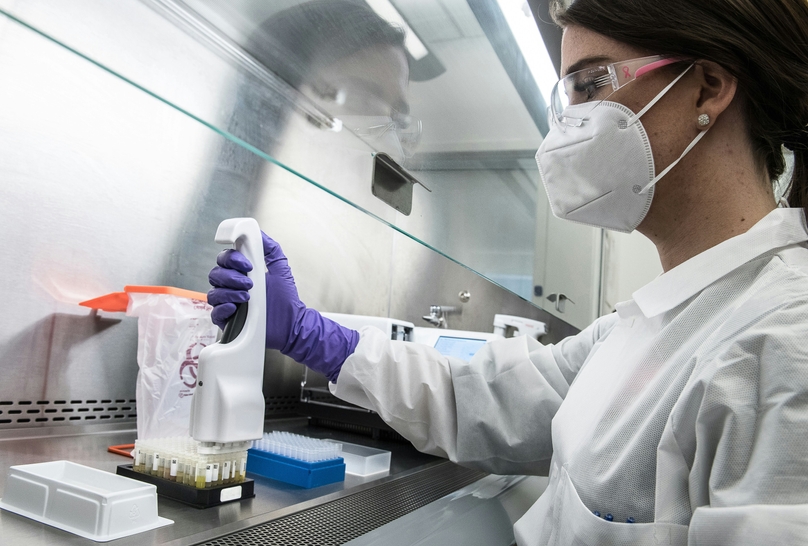

Biomanufacturing has emerged as a cornerstone in the production of vital biologics, including monoclonal antibodies and vaccines. As demand for these life-saving product grows and the industry evolves, manufacturers are under increasing pressure to optimize biomanufacturing processes.

The Growing Importance of Biomanufacturing Efficiency

As the biomanufacturing industry advances, both established leaders and emerging start-ups face growing competition in the biologics market. The increasing diversity of products demands that manufacturers maintain exceptional efficiency, quality, and safety standards, driving continuous innovation and improvement. However, optimizing biomanufacturing processes presents significant challenges due to the intrinsic complexities of biological systems and the rigorous regulatory requirements for medical product production. Efficiency and scalability have become crucial benchmarks in this field, but achieving them is no small feat.

Curious about the hurdles that stand in the way of biomanufacturing process optimization?

Scaling the biomanufacturing process from laboratory to industrial levels introduces issues such as batch-to-batch variability, where product yields and quality can fluctuate due to factors like environmental conditions, equipment inconsistencies, and biological responses. For example, scaling up monoclonal antibody production requires maintaining consistent cell densities and product titers, which becomes more difficult as small fluctuations in temperature, pH, or nutrient availability can significantly affect the final product. Biomanufacturing workflows are inherently intricate, involving interconnected stages such as fermentation, purification, and formulation. Each step must be carefully synchronized to prevent bottlenecks that can delay production and increase costs. To overcome these challenges, biomanufacturing scalability tools, such as automation and real-time monitoring systems, are essential for streamlining operations. Genemod’s cloud-based biomanufacturing software enables researchers to capture real-time data, monitor processes more effectively, and make quicker, informed decisions. In addition, biomanufacturers often face significant costs from delays in accessing essential data, especially during clinical trials. These delays are often worsened by repeated data entry at different stages, as many automated systems lack integration for seamless information sharing. Genemod’s Electronic Lab Notebook (ELN) offers a solution by incorporating built-in rules and validation checks that ensure data meets required standards, effectively identifying and resolving errors before they impact research outcomes.

If you're looking to optimize the efficiency and scalability of your biomanufacturing research, these strategies offer a roadmap to overcoming challenges and unlocking a more seamless, innovative future in medical product production.

Strategy 1 – Streamlining Process Optimization for Scalability

Scaling up biomanufacturing processes requires careful optimization of parameters like mixing times, temperature profiles, and processing conditions. Developing robust, scalable parameters is essential for ensuring confidence during clinical-scale production and achieving commercial success. However, scaling up presents challenges, including batch variability and equipment limitations. Laboratory tools are often unsuitable for industrial applications due to differences in scale, material compatibility, and operational requirements. Genemod’s biomanufacturing software offers advanced scalability tools designed to address these challenges. By enabling seamless data collection and analysis, it supports informed decision-making throughout the process. With real-time monitoring, the platform ensures process efficiency and promptly addresses deviations to uphold consistent product quality.

Strategy 2 – Enhancing Resource and Inventory Management

Efficient biomanufacturing inventory management solutions are essential for ensuring that consumables, reagents, and equipment are readily available, preventing delays in time-sensitive biomanufacturing processes. By rigorously tracking materials, including expiration dates and storage conditions, it ensures the use of high-quality reagents. Accurate monitoring of inventory levels and usage patterns allows biomanufacturers to optimize purchasing, acquiring only what is needed. Genemod’s biomanufacturing software streamlines this process by enabling real-time inventory tracking, offering immediate visibility into stock levels. Its innovative "virtual freezer" feature provides a visual representation of lab storage, allowing lab managers to quickly locate samples and reagents. This digital approach not only reduces time spent searching for materials but also minimizes errors from manual logging. Additionally, it prevents waste by limiting unnecessary thawing, as freezer doors remain open for shorter periods. Genemod further enhances efficiency with automated reordering based on usage patterns and expiration dates, ensuring labs are consistently stocked with the necessary supplies while avoiding excess inventory and waste.

Strategy 3 – Ensuring Compliance in Biomanufacturing

Biomanufacturing labs face significant challenges in achieving Good Manufacturing Practice (GMP) compliance, requiring careful technology transfer, protocol adaptation, and management of inherent variability in patient-derived materials. Ensuring batch-to-batch consistency amidst this variability demands advanced controls and strict regulatory adherence. Compliance tools for biomanufacturing labs must support robust facilities, equipment, trained personnel, and reliable processes, supported by well-maintained Standard Operating Procedures (SOPs). Managing these procedures can be complex and labor intensive, but biomanufacturing software like Genemod automatically records all user actions, creating a detailed audit trail essential for demonstrating compliance during inspections and audits. In biomanufacturing, where handling sensitive data is critical, security remains a top priority. Trusted by hundreds of leading research institutions, Genemod safeguards data with advanced encryption methods, ensuring compliance with regulations like GDPR and CCPA while maintaining data integrity and confidentiality. Genemod allows for customizable user permissions, ensuring that only authorized personnel have access to sensitive information and critical processes.

Strategy 4 – Strengthening Data Management for Scalability

As biomanufacturing processes scale, the amount of data generated increases exponentially. This includes data from experiments, production runs, quality control tests, and regulatory documentation. Traditional data management systems often struggle to handle such large datasets while maintaining accuracy, leading to potential errors in data entry or processing. These mistakes can result in flawed conclusions and reduced product quality. With operations expanding, ensuring that all data is accurate and up-to-date becomes more complex, making it challenging to ensure all necessary information is accurately recorded and easily retrievable. Genemod addresses these challenges by providing a single cloud-based platform where all research data is organized, accessed, and analyzed seamlessly. This centralization eliminates data silos and ensures that all team members have access to the same information in real time. The platform’s user-friendly interfaces allow researchers to visualize their data easily, helping to identify trends and insights quickly for informed decision-making as operations scale. As biomanufacturers grow, Genemod’s architecture supports scalability without compromising performance, offering powerful biomanufacturing process optimization along with a robust Laboratory Information Management System (LIMS) for biomanufacturing.

Strategy 5 – Promoting Collaboration Across Teams

Biomanufacturing teams often rely on varied tools and platforms for communication, which can lead to fragmented information and misunderstandings. Without a unified communication channel, these gaps can result in delays and errors during project execution. Coordinating workflows across departments—such as research, quality control, and production—becomes especially challenging when data is stored in separate systems or formats. These silos hinder collaboration, making it difficult for teams to access critical information, often leading to inefficiencies and duplicated efforts. Collaborative tool tailored for biomanufacturing, such as Genemod’s electronic lab notebook (ELN), address these challenges by streamlining data sharing and collaboration, regardless of team members' locations. Its live document editing feature allows multiple users to draft, revise, and comment on documents simultaneously, ensuring everyone has access to the latest information. Additionally, Genemod’s biomanufacturing scalability tools for assigning tasks and setting deadlines help teams stay organized and accountable, keeping projects on schedule. In fast-paced clinical settings, where generating actionable results within hours is critical, the integration of cloud storage and scalable collaborative platforms becomes essential. By enabling real-time teamwork, these solutions accelerate research processes and improve efficiency across biomanufacturing teams.

Strategy 6 – Utilizing Real-Time Insights to Drive Decisions

Accessing real-time data insights is critical in biomanufacturing laboratories, enabling teams to prioritize tasks, troubleshoot issues, and make informed decisions efficiently. Real-time updates on experiment statuses and resource availability help optimize workflow efficiency by allowing teams to focus their efforts where they are needed most. For example, if an experiment yields unexpected results, resources can be reallocated, and priorities adjusted swiftly to address the issue. Advanced biomanufacturing software like Genemod's offers automated alerts for critical events, including low inventory levels, deviations in experimental results, and sample handling issues, enabling rapid responses to potential problems. With AI-driven analytics and intuitive visualization tools, the platform provides software solutions that identify data patterns and deliver predictive insights, helping biomanufacturing laboratories anticipate future needs and outcomes. As digital transformation reshapes biomanufacturing, advanced data analytics is becoming increasingly essential for process monitoring, driving technical modernization to enhance production capabilities, efficiency, and quality.

How Genemod Drives Biomanufacturing Success?

Genemod’s cutting-edge cloud-based LIMS and ELN solutions are designed to overcome the challenges of scaling and optimizing efficiency. With robust features such as comprehensive data management, real-time collaboration, scalability, regulatory compliance, and AI-powered insights, Genemod seamlessly integrates into your current workflows. The platform is highly adaptable, allowing customization to meet diverse biomanufacturing needs. Built with AWS-level security, it safeguards sensitive data, empowering biomanufacturing labs to comply with industry regulations effortlessly.

Getting Started with Genemod!

Embrace the future of biomanufacturing with Genemod—your partner in success for a rapidly evolving industry. Our cutting-edge software is purpose-built to optimize operations in biomanufacturing research labs, adeptly addressing the unique challenges of the field. At Genemod, we specialize in helping you select and customize solutions tailored to your laboratory’s specific needs. Discover how our innovative tools can enhance the efficiency and scalability of your biomanufacturing processes.

Contact us today for a complimentary demonstration and take the first step toward streamlining your biomanufacturing processes.