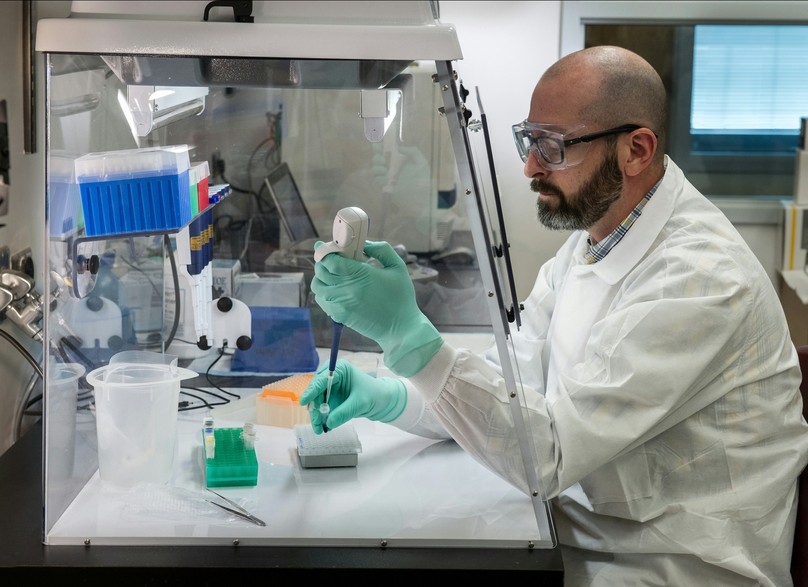

For lab service-based businesses, efficient inventory management is crucial to maintain seamless operations and deliver high-quality services. Proper inventory control ensures that essential supplies and equipment are readily available, minimizing disruptions and ensuring accurate and timely results. In this article, we will explore the best inventory management practices designed specifically for laboratory settings. By implementing these strategies, lab service-based businesses can optimize their inventory processes, streamline operations, and enhance the overall efficiency of their laboratory quality management systems.

Accurate Inventory Tracking and Recording

Accurate inventory tracking and recording form the cornerstone of effective inventory management for lab service-based businesses. Implementing a reliable inventory management system enables real-time monitoring of stock levels, ensuring that essential supplies and equipment are available precisely when needed. Meticulous recording of incoming and outgoing inventory provides valuable insights into usage patterns, enabling better forecasting and informed procurement decisions.

With a well-established tracking system, lab service-based businesses can identify trends, anticipate demand, and optimize their inventory levels. This approach minimizes the risk of stockouts, which could disrupt operations and compromise service quality. Additionally, accurate record-keeping fosters data integrity, which is essential for complying with regulatory standards and maintaining the overall efficiency of the laboratory quality management system.

By prioritizing accurate inventory tracking and recording, lab service-based businesses can streamline their operations, reduce waste, and enhance customer satisfaction through timely and reliable service delivery.

Implementing Barcode Technology

Utilizing barcode technology is a game-changer for lab service-based businesses aiming to enhance inventory management. Barcoding facilitates rapid and error-free tracking of inventory items, minimizing the risk of human errors associated with manual data entry. Scanning barcodes during receipt, usage, and restocking of supplies not only improves data accuracy but also expedites inventory-related processes, leading to greater efficiency and reduced operational costs.

Demand Forecasting and Planning

Demand forecasting and planning play a pivotal role in optimizing inventory management for lab service-based businesses. By analyzing historical data, usage patterns, and other relevant factors, labs can anticipate future needs more accurately. This proactive approach enables them to maintain optimal stock levels, preventing both stockouts and excess inventory.

A well-executed demand forecasting and planning strategy empowers lab service-based businesses to align their inventory with anticipated demand, ensuring essential supplies and equipment are readily available. It minimizes operational disruptions, maximizes resource utilization, and reduces holding costs. Additionally, forecasting enables labs to be agile and responsive, adapting quickly to changes in demand and seasonal fluctuations.

Establishing Inventory Reorder Points

Setting inventory reorder points is a strategic approach to maintaining optimal stock levels. By identifying minimum stock thresholds, lab service-based businesses can trigger the replenishment process automatically when inventory levels reach predetermined points. This proactive approach ensures that essential supplies are reordered in a timely manner, mitigating the risk of stockouts and disruptions in service delivery.

Effective inventory management is a crucial aspect of optimizing laboratory quality management systems in lab service-based businesses. Accurate tracking and recording of inventory, implementation of barcode technology, demand forecasting, and establishing inventory reorder points are essential best practices that can streamline operations, reduce costs, and enhance efficiency.

By adopting these strategies, lab service-based businesses can maintain seamless operations, deliver high-quality services, and ensure that essential supplies and equipment are always readily available when needed. A well-executed inventory management approach contributes to the success of laboratory operations and the overall satisfaction of customers and stakeholders.