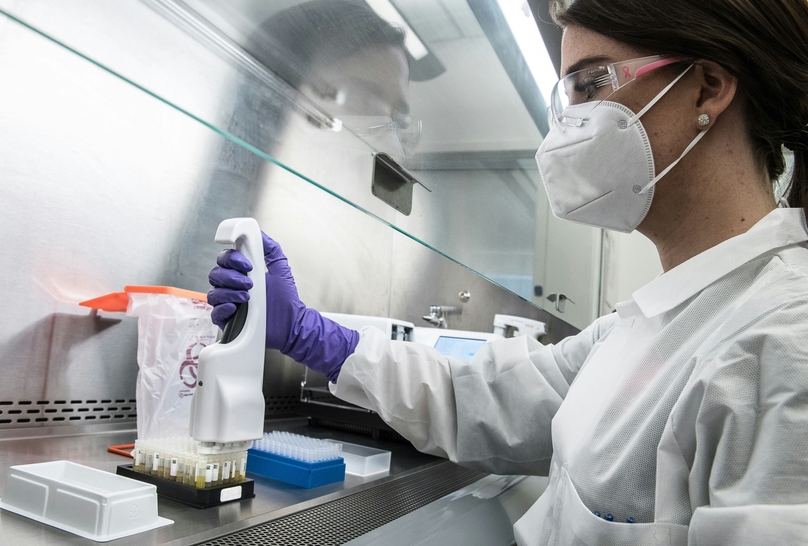

Effective inventory tracking is essential for maintaining the smooth operations of any laboratory. Accurate inventory management not only prevents disruptions in research but also saves time and resources, and ultimately enhances productivity. In this article, we'll provide you with step-by-step instructions on how to track inventory in your lab, ensuring that your supplies are organized, accessible, and well-managed.

Define Your Inventory Categories

Begin by categorizing your lab inventory. Divide items into logical groups such as chemicals, consumables, equipment, reagents, and instruments. This segmentation will serve as the foundation for your inventory tracking system.

Choose an Inventory Tracking System

Select an inventory tracking system that aligns with the scale and complexity of your lab. You can opt for manual methods using spreadsheets or leverage specialized laboratory information management systems (LIMS) software. LIMS can offer automated tracking, real-time updates, and customizable reporting.

Establish a Centralized Storage System

Designate a central storage area for your lab inventory. This ensures that all items are stored in a consistent location, making it easier to locate and replenish supplies when needed. Each shelf or storage unit should correspond to a specific inventory category.

Label Everything

Labeling is crucial for easy identification. Attach clear labels to shelves, cabinets, and individual items. Use a standardized naming convention and include relevant information such as item name, quantity, and expiration date if applicable.

Create a Digital Inventory Database

If using a manual system, set up a digital inventory database using spreadsheet software like Microsoft Excel or Google Sheets. Create columns for item names, categories, quantities, reorder points, and any other pertinent information. Regularly update this database as items are used or restocked.

Implement a Tracking Process

Define a clear process for adding and removing items from inventory. When new supplies arrive, record them in your inventory database immediately. Similarly, when items are used, mark them as such in the database. This process will help maintain an accurate record of stock levels.

Set Reorder Points

Determine reorder points for each item in your inventory. Reorder points are the minimum quantities at which you should initiate the process of restocking. When an item's quantity reaches its reorder point, it's time to place an order to prevent stockouts.

Regular Audits

Schedule regular inventory audits to ensure the accuracy of your database. Perform physical checks of the items in your storage area and compare them with the data in your inventory tracking system. Any discrepancies should be investigated and resolved promptly.

Train Your Team

Ensure that your lab members are well-versed in the inventory tracking process. Provide training on how to record items, update quantities, and follow proper procedures for restocking. Clear communication and adherence to the process by all team members are essential for successful inventory management.

Utilize Technology

If your lab employs LIMS or other laboratory management software, leverage its features for enhanced inventory tracking. Many systems offer barcode or RFID scanning capabilities for efficient item identification and updates.

Monitor Trends and Optimize

Regularly analyze your inventory data to identify consumption trends, overstocked items, or items that frequently run low. This information will help you optimize your inventory management strategy, adjust reorder points, and allocate resources more effectively.

Continuous Improvement

Inventory tracking is an ongoing process. Regularly review and refine your procedures based on feedback from lab members and the results of your tracking efforts. Continuous improvement ensures that your inventory management remains efficient and adaptive to changing needs.

Effective inventory tracking is a cornerstone of efficient lab operations. By following these step-by-step instructions, you can establish a robust system that keeps your lab stocked, organized, and ready for research excellence. Whether you choose a manual approach or leverage technology, consistent and accurate inventory management is a vital asset to any laboratory.