Why FreezerPro Is No Longer Enough for Modern Sample Management — And What Scaling Labs Need Instead

FreezerPro helped many labs move beyond spreadsheets with freezer mapping and barcode tracking. But in 2026, inventory expectations have changed—labs need lifecycle context, workflow connectivity, and analytics, not just location tracking.

FreezerPro is widely known as a sample inventory management system. For many labs, it has served as a structured alternative to spreadsheets — offering freezer mapping, barcode tracking, and organized storage hierarchies.

But in 2026, inventory management expectations have changed.

Labs no longer just need to know where a sample is. They need to understand its full lifecycle, experimental context, lineage, operational status, and downstream impact.

And when measured against those expectations, FreezerPro increasingly feels limited — even as an inventory tool.

The Problem: Inventory Today Is About Context, Not Just Location

FreezerPro focuses heavily on storage structure:

- Freezers → racks → boxes → positions

- Barcode assignments

- Sample attributes

- Movement logging

That structure provides location clarity. But modern inventory management requires more than positional accuracy.

Scaling labs need:

- Automatic lineage tracking

- Tight linkage between samples and experiments

- Status-based workflow awareness

- Ownership visibility

- Integrated request handling

- Audit-ready traceability

Without those capabilities embedded into the inventory layer itself, teams end up compensating with:

- Manual status tracking

- Parallel spreadsheets

- External documentation tools

- Email-based coordination

At that point, inventory becomes fragmented. The freezer might be organized—but the sample lifecycle is not.

Where FreezerPro’s Inventory Model Falls Short

Even purely from an inventory perspective, labs often encounter structural limitations:

Inventory Is Isolated from Execution

FreezerPro tracks samples, but experimental activity often lives elsewhere. This separation creates a disconnect between “what exists” and “what is happening.”

Limited Lifecycle Visibility

Tracking storage location is different from tracking lifecycle state. Labs need to know whether a sample is pending QC, reserved for a study, released, archived, or deprecated.

Weak Operational Signals

Inventory systems should help answer operational questions:

- Which samples are over-utilized?

- Which storage areas are under capacity?

- Where are samples stuck in processing?

Without workflow context, these signals remain invisible.

Minimal Analytical Depth

Inventory management in 2026 should enable pattern detection — not just lookup. Identifying repeated freeze-thaw cycles, recurring QC failures, or usage patterns requires structured connectivity beyond simple storage attributes.

FreezerPro was designed for freezer organization.

Modern labs need inventory intelligence.

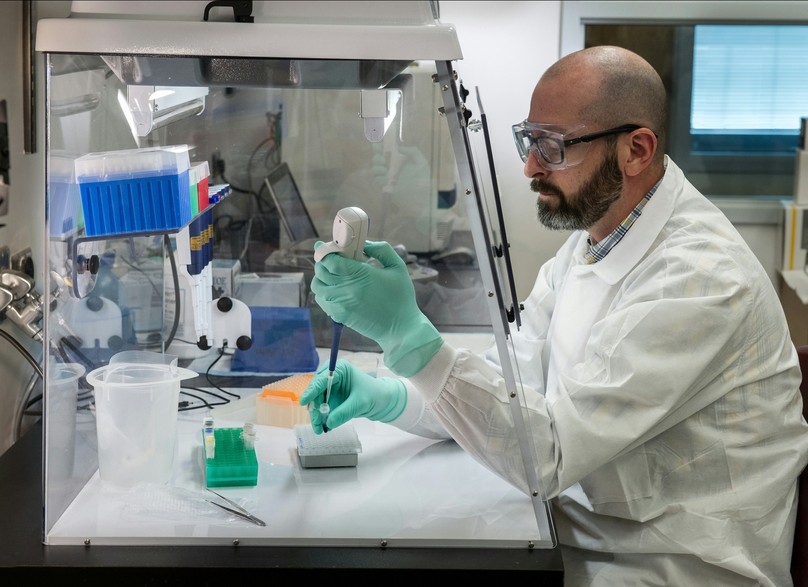

How Genemod Delivers Stronger Inventory Management

Genemod treats inventory as a core operational layer — not a static storage map.

Inventory in Genemod is built around lifecycle awareness, contextual connectivity, and execution visibility.

1. Lifecycle-Aware Sample Management

In Genemod, every sample carries:

- Structured metadata

- Status states

- Ownership assignments

- Linked experiments

- Full lineage history

Location is only one attribute among many.

Because lifecycle state is embedded into the inventory model, labs can see:

- What is available

- What is in progress

- What is reserved

- What is QC-pending

- What is archived

This transforms inventory from passive tracking into active management.

2. Native Sample-to-Experiment Connectivity

Unlike systems where inventory and documentation are separate, Genemod directly connects:

Samples → Experiments → Results → Files → Approvals

When a sample is used in an experiment, that relationship is automatically preserved. No duplication. No manual reconciliation.

This means inventory answers not only “Where is it?” but also “What has happened to it?”

3. Operational Intelligence Built Into Inventory

Because Genemod integrates workflow and sample tracking, labs gain:

- Visibility into bottlenecks

- Clear handoff points between teams

- Capacity awareness across storage

- Usage frequency tracking

- Automatic audit trails

Inventory becomes a management tool — not just a lookup table.

4. Inventory Designed for AI-Driven Insight

Modern inventory management must support AI.

Genemod’s structured, connected data model allows labs to:

- Detect abnormal usage patterns

- Identify samples at risk of degradation

- Surface inconsistencies in metadata

- Predict workflow delays

AI cannot operate meaningfully when sample data is isolated from operational context.

Genemod’s architecture makes inventory analysis dynamic, not static.

And Beyond Inventory: A Unified Operational Platform

The advantage does not stop at inventory strength.

Genemod integrates:

- ELN functionality

- Workflow orchestration

- Request management

- Permissions and governance

- Structured metadata controls

- File management

- Audit readiness

This means labs do not need to stitch together multiple systems to manage execution.

Inventory is embedded inside a broader operational backbone.

The Bottom Line

FreezerPro helped many labs move beyond spreadsheets and manual freezer maps.

But modern R&D operations demand more than organized storage.

Inventory management in 2026 must:

Preserve full sample lifecycle context

Connect natively to experiments and results

Provide real-time operational visibility

Surface analytical and AI-driven insights

Scale without introducing system fragmentation

Genemod is built specifically for this new standard.

It delivers stronger, lifecycle-aware inventory management while embedding that inventory inside a unified LIMS + ELN execution platform.

That means:

No disconnected systems for samples and experiments

No parallel spreadsheets for status tracking

No manual reconciliation between freezer records and documentation

No ceiling when operational complexity increases

If your lab is scaling, inventory cannot remain an isolated tool. It must become part of your operational backbone.

Genemod does not simply replace FreezerPro’s inventory functionality.

It upgrades it — and future-proofs it — by combining intelligent sample management with workflow orchestration, structured experiment data, governance controls, and AI-ready architecture.

In 2026, the real question is no longer:

“Is our freezer organized?”

The real question is:

“Is our inventory system helping us run the lab — or just record it?”

Genemod is built to help you run it.